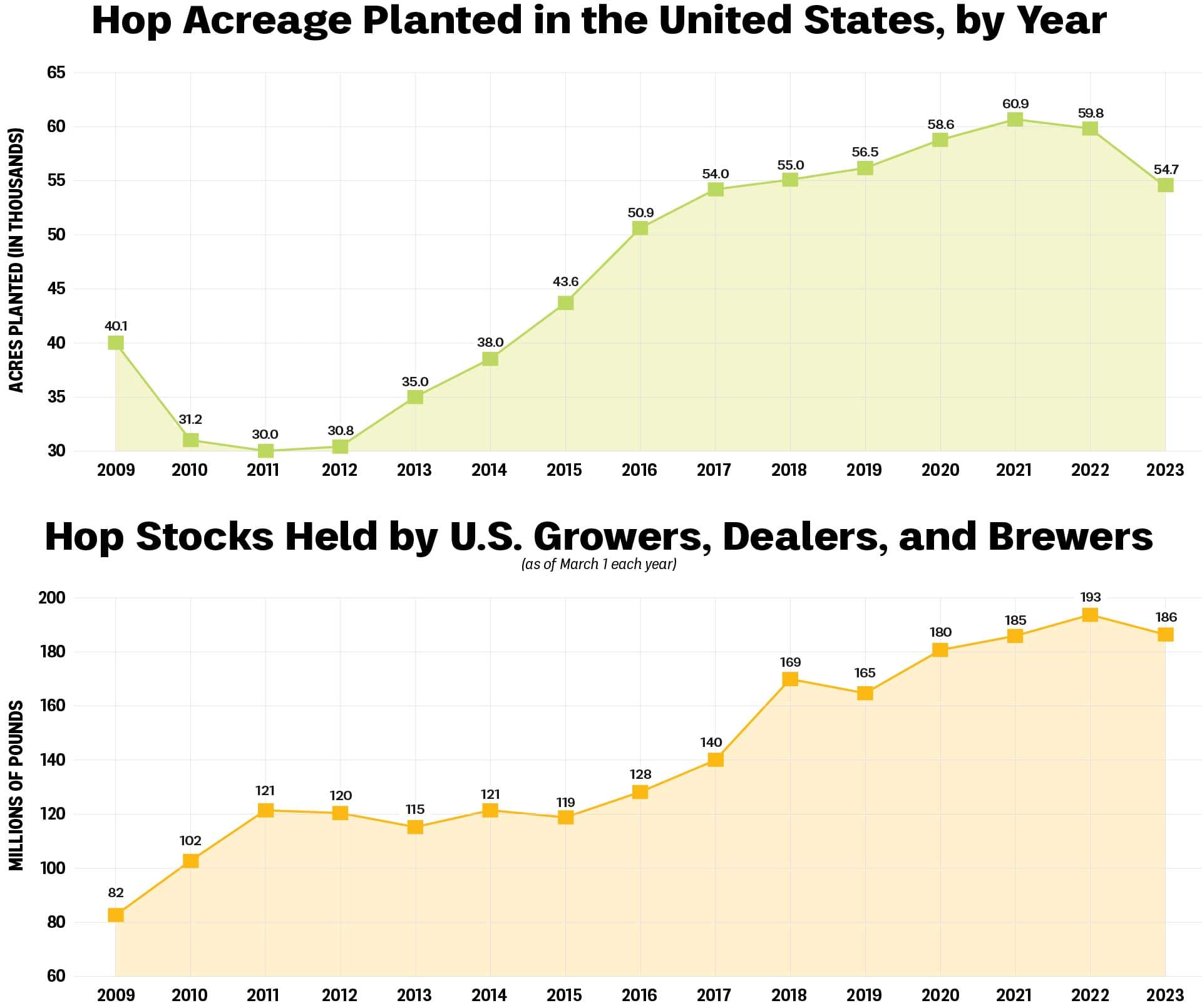

Hop Harvest 2023: Inching Toward Equilibrium

ALL ACCESSWhile the numbers are far from final, there were modest steps toward rebalancing the market for U.S. aroma hops. Centennial and Simcoe had a rough year, while rain helped Germany and Czechia avoid a second consecutive disastrous harvest.