Ready to Tango? New Hop Varieties on the Way

ALL ACCESSFrom Anchovy to Vista, here are some interesting hop cultivars on the immediate horizon—plus a couple of experiments that may be the next to get names.

Showing 361-380 of 833 articles

From Anchovy to Vista, here are some interesting hop cultivars on the immediate horizon—plus a couple of experiments that may be the next to get names.

From our upcoming Spring issue of the Brewing Industry Guide, here’s a roundup of some recent news, notes, and announcements from around the industry.

You see them on TikTok and Instagram, posing or even lip-syncing while proudly showing off a can of another brewery’s beer. Who are these people? Should you engage or avoid? And what’s the ROI?

Devices that monitor fermentation in real time and apps that make data analysis a snap can help improve quality and output. They can also save breweries money, reducing the chances for error.

In demand and on trend, hop water is proving to be a low-effort, high-reward offering for many small breweries.

Led by Ukraine’s first Cicerone, an international effort aims to rally brewers and drinkers to raise funds for humanitarian relief.

Some brewers are turning to heritage barley varieties for malts that can add new character to their beers—and attract new fans.

The Heidelberg-based maltster is inviting brewers around the world to brew an altbier with Bestmalz ingredients and enter their competition.

While hop harvest commences in the Southern Hemisphere, field work is already under way on many hop farms in the North. Here are some things that brewers should know about the season to come.

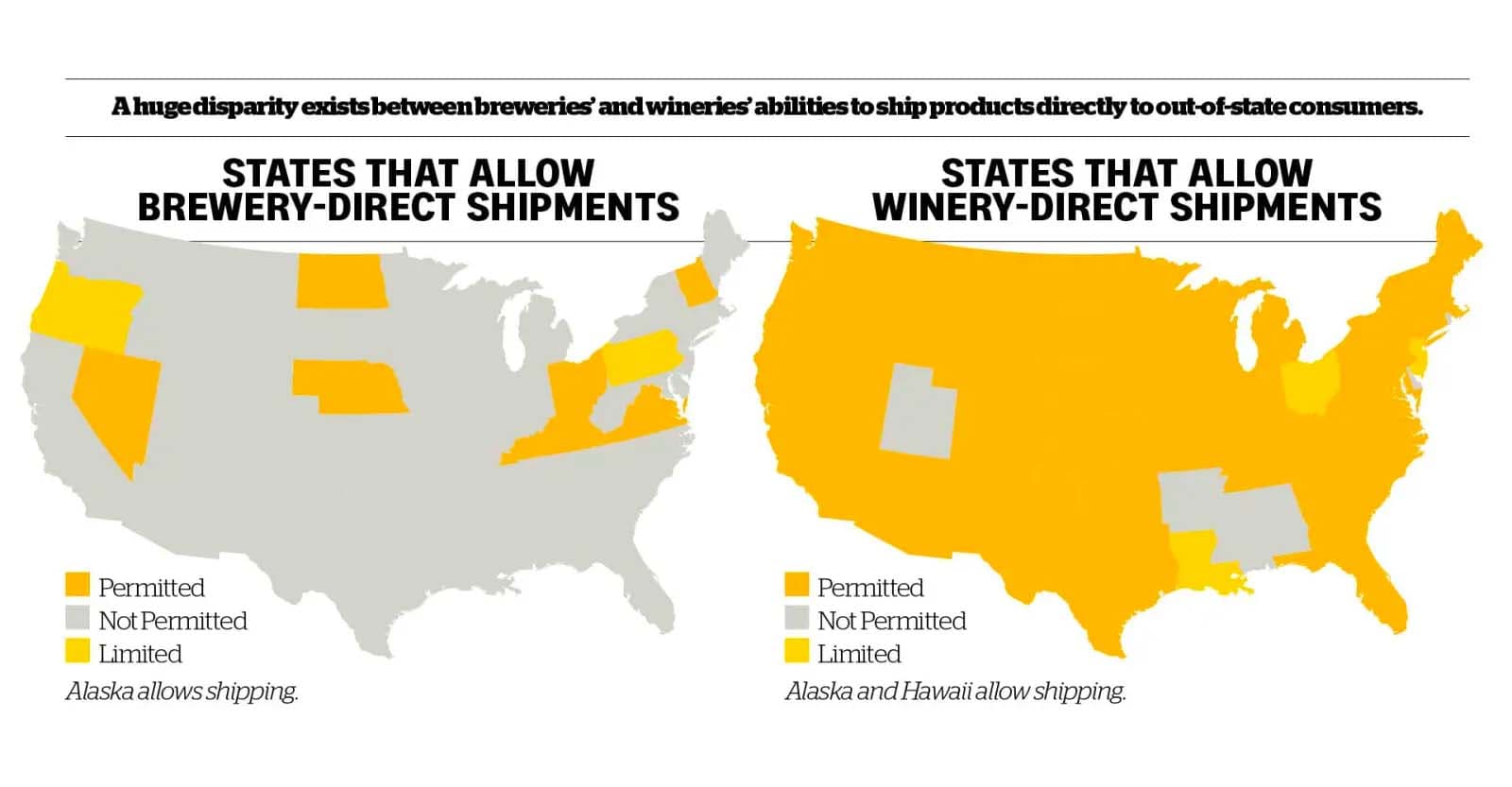

While the pandemic has led to a general loosening of restrictive Prohibition-era laws regarding beer for takeaway and delivery, there’s still plenty to do to liberalize the United States’ antiquated approach to alcohol regulation.

Online alcohol marketplaces such as Drizly and Instacart aren’t just for big beer. Here’s how craft suppliers can work with retailers to boost sales on these platforms.

North Carolina’s Fonta Flora Brewery now operates three taprooms and a farm, as the company learns how to bridge the gap not just between urban and rural, but also between idealism and reality.

Expensive equipment and a steep technical learning curve make contract brewing nonalcoholic beers an attractive option for smaller breweries.

Brewers willing to try new things and push the boundaries of flavor helped to create a market that now evolves at breakneck pace—a market full of challenges and opportunity.

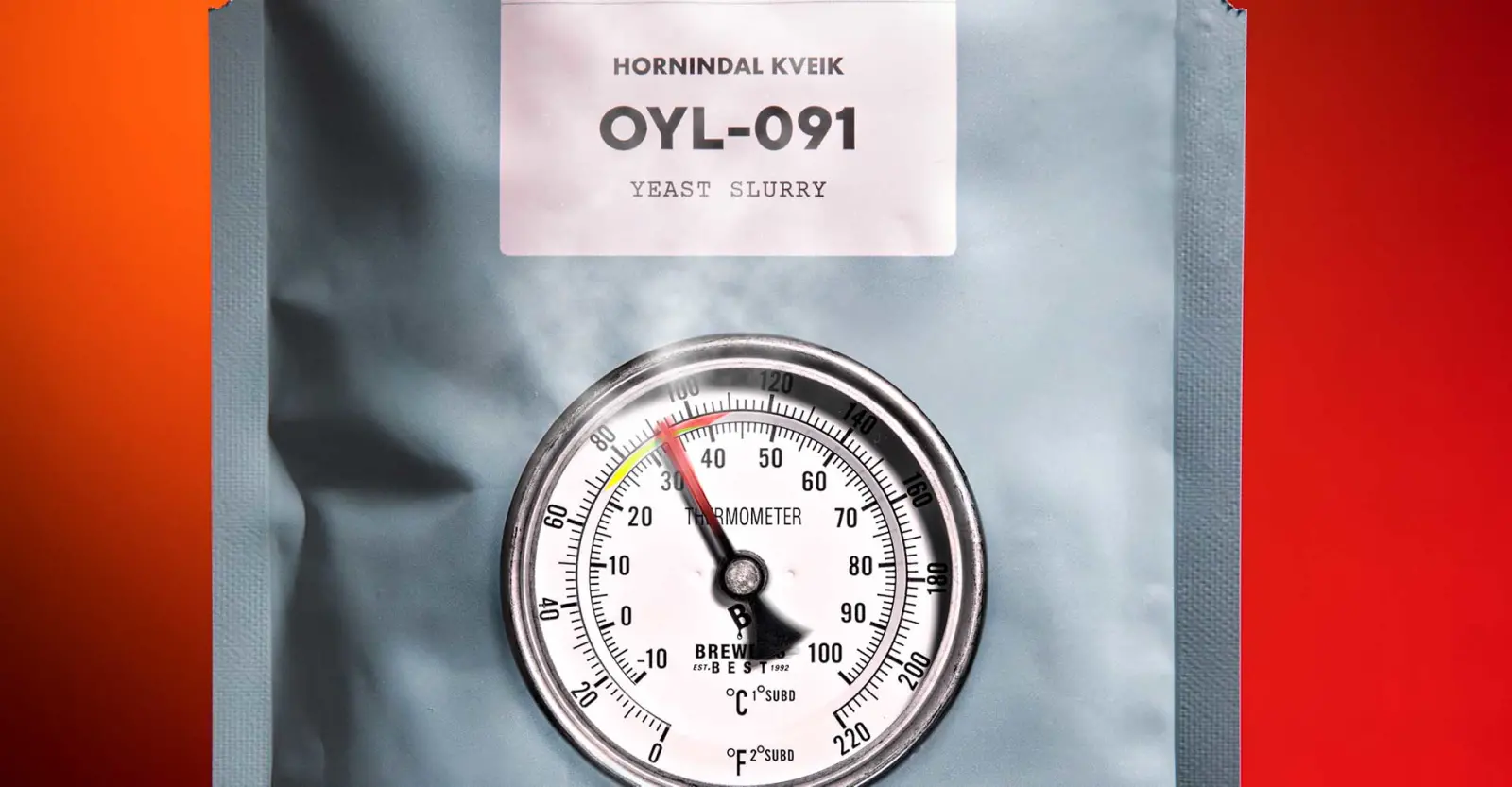

Yeast labs are enjoying sales success with clean kveik strains, since their ability to ferment lager-like beers in much less time has obvious appeal. Besides reduced costs and climate impact, they are potential game-changers for hotter climates worldwide.

It’s not all four-packs and boss pours. Glassware chosen to elevate particular kinds of beer—and to help you sell more of it—still has a valued place at the bar and taproom.

In this first installment of a series focusing on the long-term outlook for hops—and issues likely to affect brewers beyond 2022—Stan Hieronymus considers hop stunt viroid, as well as the future of the hop upon which American craft was built.

In Bellingham, Washington, the cozy Otherlands brewery-café offers a lesson in Old World–inspired hospitality—as well as the risks and potential rewards of sticking stubbornly to a vision for your business.

Sales of imperial IPAs are outpacing their standard-strength counterparts. Yet breweries need to find the right packaging mix, price point, recipe, and marketing to keep margins in line.

After the purchase by the energy drink maker, the collective that includes Cigar City and Oskar Blues still counts as “craft,” according to the Brewers Association.